“Honestly, I was a bit skeptical of the claims. Every 8 claims to have clarity on the low string, and to be ‘very playable’ for an 8. They all claim it. They never deliver.

“This one delivers.

“The most playable 8 neck ever.

“I asked Rick if the string spacing was tighter. Because it was so easy.

“He said no.

“I asked him again.

“He said no. Again.

“The neck shape. Jeez. I could actually play thumb over chords on it. And the 8th string is clear.

“Guitar might look beastly in a pic. In person…it’s even more beastly in some ways…as it’s way more 3-D in person than in photos.

“But it is actually not large in your hands. Feels very light (7.25 lbs). The contour cuts make it feel small on your body.

“Did I mention that neck profile?”

(Steve Sjuggerud )

“The cleans on LAW are insane-o”

(Chris Buono)

“In a word. Breathtaking. When I took it out of its case for the first time, that feeling of the air momentary leaving the room was definitely there. (there were no shortage of gasps in the music store where I unveiled it, either).

“I don't even know where to start. It's perfect. The weight. The neck profile. The ergonomics. Actually, I need to at least address that part for a moment...looking at pictures, you led to believe sure, it's probably relatively comfortable, but it's so angular and jagged in appearance, I just assumed some compromise was to be made. (and I was OK with that. You "can't have your cake and eat it, too", right?) WRONG. Almost like an illusion, as soon as LAW is placed in your lap the entire instrument just becomes one with me. Had I flown to your place and we physically measured the body against mine and cut around it, I still can't imagine this being any more perfect than it is.

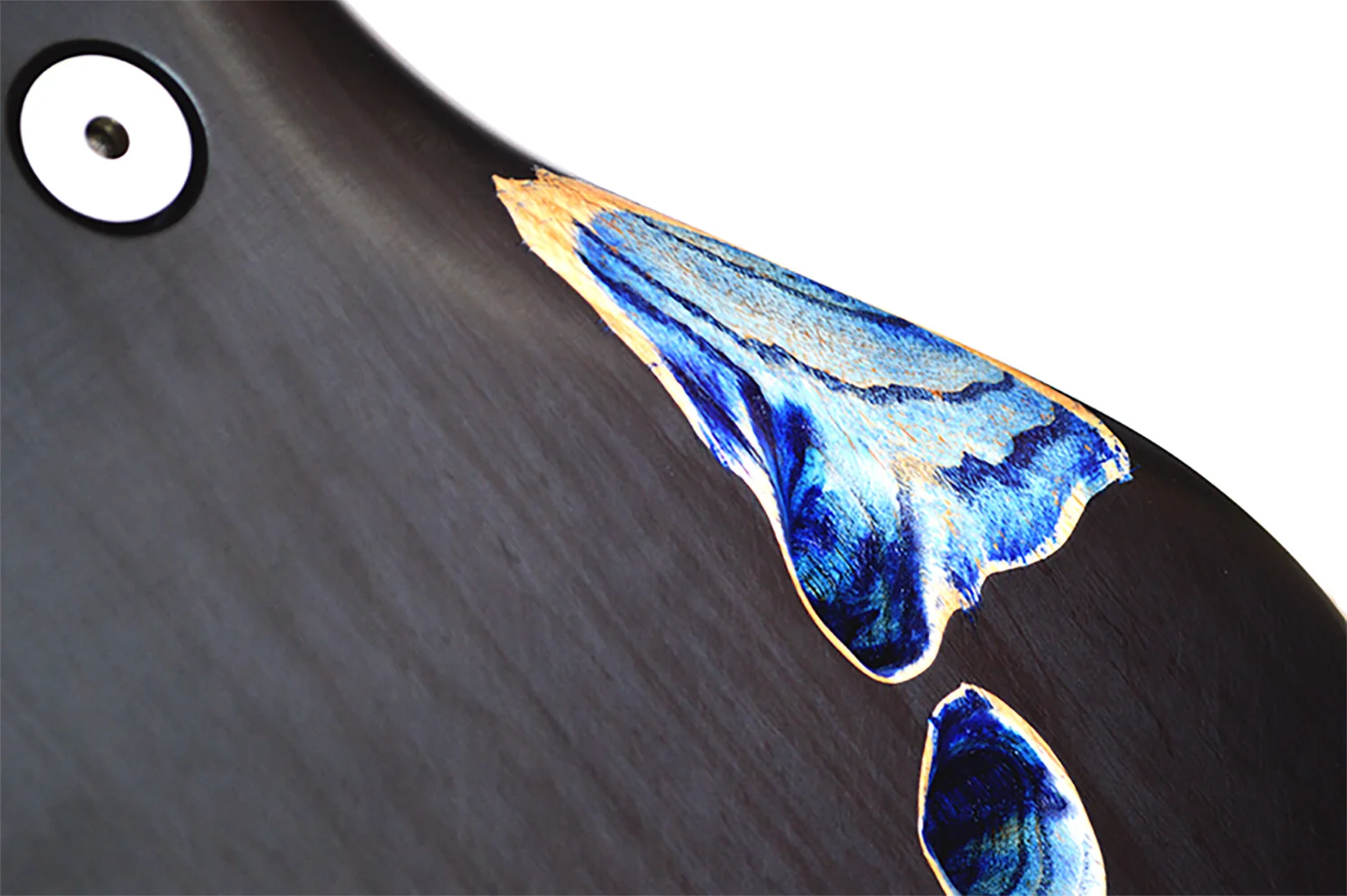

“Little Angle Wing is light, but not so much it feels like a toy. It's beastly, but also delicate. (as a butterfly?). How one guitar can be so many things at once is almost an enigma, but that, I am coming to understand, is what Rick Toone does best. Anyone can build guitars. You create vehicles for musical inspiration. Even as I type this, LAW sitting a few feet away, inspires. It somehow has the ability to strike, fear, awe, and wonder, in equal parts.

“I can't thank you enough for working with me and helping me bring this one home.” (Matt Richards)

Angle Wing butterflies are experts at biomimicry, adapted to camouflage themselves against dead leaves in the forests of North America. Freeway™ 6-position blade switch. DiMarzio™ pickups. Swamp Ash body. Intonation Cantilever™ patented solo tuner-bridges machined from stainless steel and bearing bronze. Element™ single billet machined aircraft aluminum neck. (PURCHASING INFO)